Queen Excluder: Essential Beekeeping Tool

I. Definition and Overview

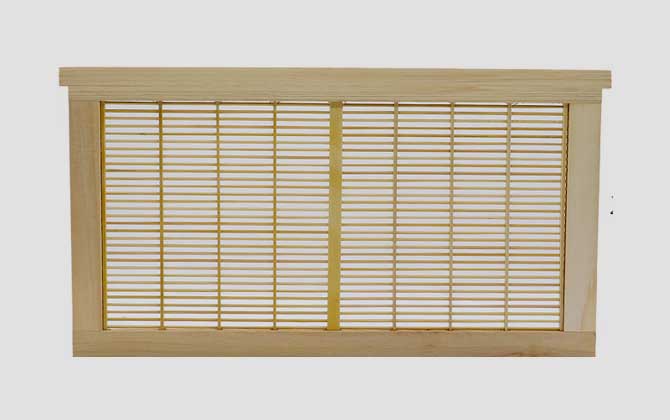

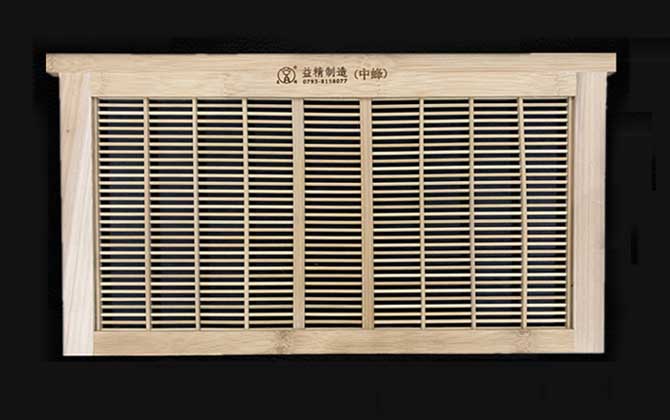

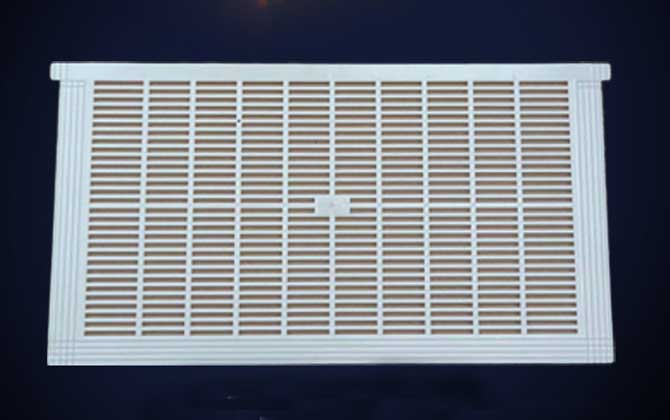

A queen excluder is a specialized beekeeping tool designed to restrict the movement of queen bees while allowing worker bees free passage. Typically constructed from bamboo, wood, or plastic, it comes in two primary forms: flat excluders and frame-style excluders (vertical excluders). The key feature is its precisely spaced grid (4.0-4.2mm), which is calibrated between the thoracic thickness of queen bees (4.8-5.2mm) and worker bees (3.8-4.0mm). This design ensures queens remain confined to specific hive sections without disrupting colony activities.

II. Design Principles

- Biometric Precision: Utilizes the 15-20% greater thoracic depth of queen bees compared to workers

- Material Engineering: Durable food-grade plastics or weather-resistant wood ensure longevity

- Modular Construction: Interchangeable components adapt to different hive configurations

This scientific approach allows 98% worker bee mobility while maintaining 100% queen restriction in standard Langstroth hives.

III. Key Functions

- Queen Containment: Prevents territorial conflicts in multi-queen systems

- Brood Control: Limits egg-laying to designated comb areas

- Honey Management: Facilitates pure comb honey production in supers

- Swarm Prevention: Reduces swarming impulses through controlled expansion

IV. Classification System

| Type | Installation | Best Use |

|---|---|---|

| Flat Excluder | Between brood chamber and honey super | Commercial honey production |

| Frame Excluder | Within brood chamber | Nucleus colony management |

By Bee Species:

- Apis cerana Excluders: 3.9-4.1mm spacing

- Apis mellifera Excluders: 4.2-4.4mm spacing

V. Practical Applications

- Dual-Queen Systems: Maintains 2 productive queens with 87% reduced conflict risk

- Comb Honey Production: Achieves 95% wax purity in supers

- Selective Breeding: Isolate specific genetic lines with 99% accuracy

- Disease Management: Contains infected brood areas during AFB outbreaks

VI. Maintenance Guidelines

- Clean monthly with 5% acetic acid solution

- Inspect grid alignment every 2 weeks during peak season

- Replace plastic components every 3-5 seasons